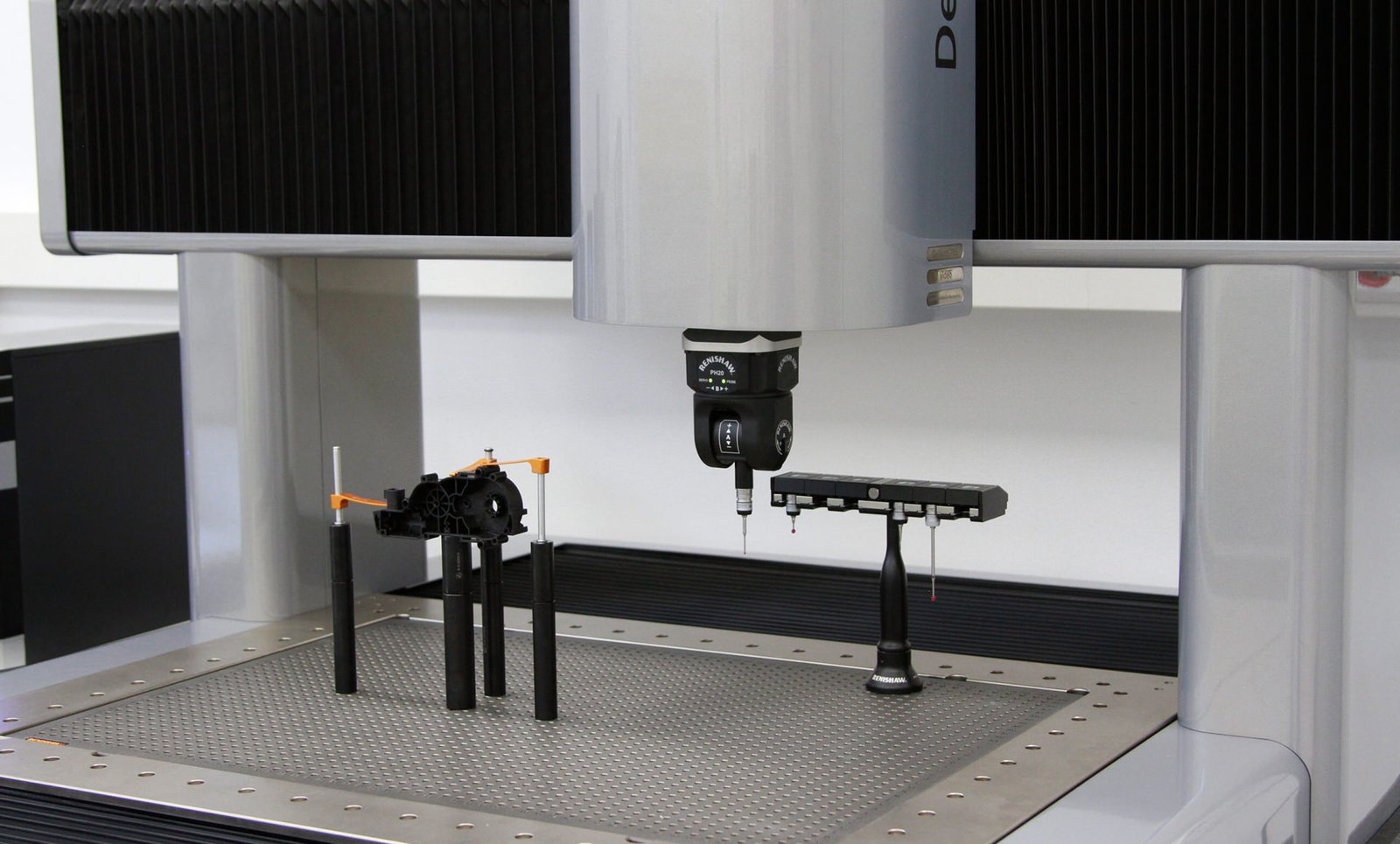

DeMeet 5-axis measuring machine

DeMeet creates an all-round measuring machine for the qualitiy management with a market-conform 5 axis controlled probe. They create an excellent price-performance ratio, the DeMeet measuring machines are equiped with a Renishaw PH20 measuring head and enable this way the most modern and precise Quality control, in production and in the measuring laboratory, with top speeds during the measuring process. Application of CNC probe measurements are for example the precision- and medical-, plastic and electronics- industry. To shorten the measuring time of conventional measuring tasks with switching buttons, the speed of the CMM axes has to be increased. The PH20's "Head Touch" method minimizes dynamic CMM errors at high measurement speeds. The PH20 System's unique "Head Touch" method allows the acquisition of measurement points through the movement of the probe, not the CMM structure. Points are captured faster and with greater precision and repeatability. In addition, time-consuming indexing of the head is no longer necessary thanks to the 5-axis movement. Together, these speed increases typically give three times higher measurement throughput compared to traditional systems.

Renishaw PH20 5-axis measurement

Up to now, the speed of the CMM axes had to be increased in order to shorten the measuring time for conventional measuring tasks with switching probes. The "Head Touch" method of the PH20 minimizes the dynamic CMM errors at high measuring speeds. The unique "Head Touch" method (head probing) of the PH20 system enables the acquisition of measuring points by moving the measuring head and not the CMM structure. Points are captured faster and with greater precision and improved repeatability. In addition, time-consuming indexing of the head is no longer necessary thanks to the 5-axis movement. Together, these speed increases typically result in a measurement throughput that is three times higher than that of conventional systems. More about Renishaw PH20

DeMeet Design and Quality

The application of quality components made by Schut and by well-known, specialized manufacturers ensures excellent performance and high accurate measurements. With the new design of the DeMeet measuring machine series no concessions have been made to accuracy and reliability. The new visually screwless cover design provides a better protection in the production environment and is highlighted with nickel-plated aluminum details which can be personalized. The open design of the DeMeet allows for easy operation and loading of the machine from all sides. The accuracy of the DeMeet measuring machines is guaranteed by a CAA 3D correction model (Computer-Aided Accuracy, error compensation).

DeMeet Machine construction

The DeMeet 3D CNC coordinate measuring machines are designed with a proven fixed bridge construction and moveable measuring table for high accuracy and accessibility. The completely covered drive system and integrated damping make the DeMeet machines very suitable for inline measuring on the production floor. The construction is a granite base plate with accuracy grade according to DIN 876/00, placed on well positioned shock absorbing points and resting on a welded base frame (for the DeMeet-220 the base plate is flat grinded cast iron). The XYZ base structure for the THK precision preloaded caged ball linear guides is made from extremely tension relieved, flat grinded cast iron, as the basis for a mechanical accurate construction. The axis drive system consists of Faulhaber high torque DC servo motors, TFE coated Kerk lead screws and Renishaw TONIC optical linear encoders with low sub-divisional error. The measuring table is made of tension relieved, wear-resistant, nickel-plated steel, with a mounting hole pattern for product fixtures and a flat aligned glass plate. The video model consists of a DeMeet camera with a Sony sensor and a telecentric optical system. In addition to the optical system the Combo model is equipped with a Renishaw touch probe system.

Tastermodule und Taster

Standardmäßig wird ein Renishaw TP20 System mit einer 5-Wege Tasterkonfiguration geliefert. Auf Anfrage sind verschiedene Tastermodule, Systeme und Tasterkonfigurationen verfügbar. Mehrfache Tastermodule können verwendet werden, um die Tasterkonfiguration auf dem Modul zu belassen und um eine kürzere Rüstzeit bei Messungen zu erreichen, bei denen andere Tasterkonfigurationen erforderlich sind. Zusätzlich zu dem Standard Tastsystem kann optional ein Wechselrack (automatische Taster-wechselkonfiguration) verwendet werden. Mit dem Tasterwechselrack können Tastermodule innerhalb eines Messablaufes automatisch aus-getauscht werden.

Taster Qualifikation

Die Maschine wird geliefert mit einem Positionsversatznormal, erforderlich für die Bestimmung des Objektiv/Tasterversatzes, einem Gesichtsfeld Einstellnormal, erforderlich für die Gesichtsfeld Kalibrierung (Optisch) und die Qualifikationskugel, inklusive Kalibrierbericht, für die Taster (Taster) Qualifikation (Position und Größenbestimmung). Mehr über Tastermodule und Taster

Renishaw MODE software package

MODUS ™ offers a comprehensive range of three-dimensional measurement functions, which is provided via an intuitive user interface with a graphic output of the measurement routines. With the help of software assistants, common measurement activities can be specified quickly and easily to ensure that the use even without special programming skills. All measurement results from the video and probe can be displayed, logged, exported and in CAD files and are dynamic updated. The measurement results can also be displayed together in a 3D view.

REVO 5-axis measurement

MODUS ™ offers a range of assistant powered commands for defining individual 5-axis measurements such as "helical scans". Clear, precise graphic measurement protocols - with fully user-configurable headers, labels, texts and pictures. More about Renishaw MODUS SoftwareFixture systems for DeMeet

A secure positioning of the measurement object is crucial for an accurate measurement result and the clamping system can also be used for pallet measurements. DF Fixture system DF-System is a fixture system developed and produced by Schut and designed for constructing 3D product fixtures, particularly for optical measurements, and is fully compatible with the measuring table of the DeMeet measuring machines. Alufix Fixture system Alufix is a flexible fixture system made of high-tensile aluminum. Alufix is a uniquely designed modular fixture system to prepare a product-fixture in a short time and is easy to mount and specially suitable for fixtures for heavier measuring objects Specialized Fixture systems If products have to be measured on a pallet where a standard fixturing system does not offer a correct solution - for example due to the unusual shape or small dimensions of the product - then a customized system can be the solution. More about Fixture systems

Spezifikationen Taster Messmaschinen

Information

Klicken Sie hier unten bitte auf die jeweilige Überschrift, um weitere Informationen zu erhalten.

Allgemein

|

Tastsystem |

Renishaw |

|

Messtisch |

Befestigungsbohrungen 33 Einsätze M8 |

|

Antrieb |

DC Servomotoren / Luftlagerführungen |

|

Bedienung |

Joystick-Steuerung / komplett CNC-gesteuert |

|

Basis |

Hartgesteinplatte, Portal und Z-Achse: Granit (DIN 876/00) |

Messspezifikationen

|

Messbereich |

(mm) |

X = 500, Y = 715, Z = 400 |

|

Abmessungen |

(mm) |

B = 1182, L = 1404, H = 2255 |

|

Gewicht |

(ca. kg) |

1200 |

|

Max. Gewicht Messobjekt |

(kg) |

400 |

Speisung

|

Auflösung (µm) |

0,5 (0,1 optional) |

|

|

Genauigkeit 0,5 µm Ausführung (µm) (L in mm) |

2,7 + L/300* |

|

|

Genauigkeit 0,1 µm Ausführung (µm) (L in mm) |

U3 (XYZ) = 1,9 + L/400 |

* |

|

Max. Geschwindigkeit (mm/s) |

X, Y = 400, Z = 300 |

|

|

* Die Genauigkeit des Tastsystems ist zu berücksichtigen. |

||